Project inception

This project was conceived in part because it seemed fun, but also as a way to hone my research and design skills. The design of an electric motor is highly dependent on multiple factors to get the desired performance. It requires an understanding of the fundamental principles underlying this type of device. The video here shows the second test of the completed motor, running from an admittedly very under powered driver for demonstration purposes.

Design research

One of the most important factors is selecting the correct number of magnetic poles and slots for coil windings. This determines many important characteristics of the motor, such as its ability to self-start and is a contributing factor to its efficiency. A lot of background research was done on this point to select the correct combination.

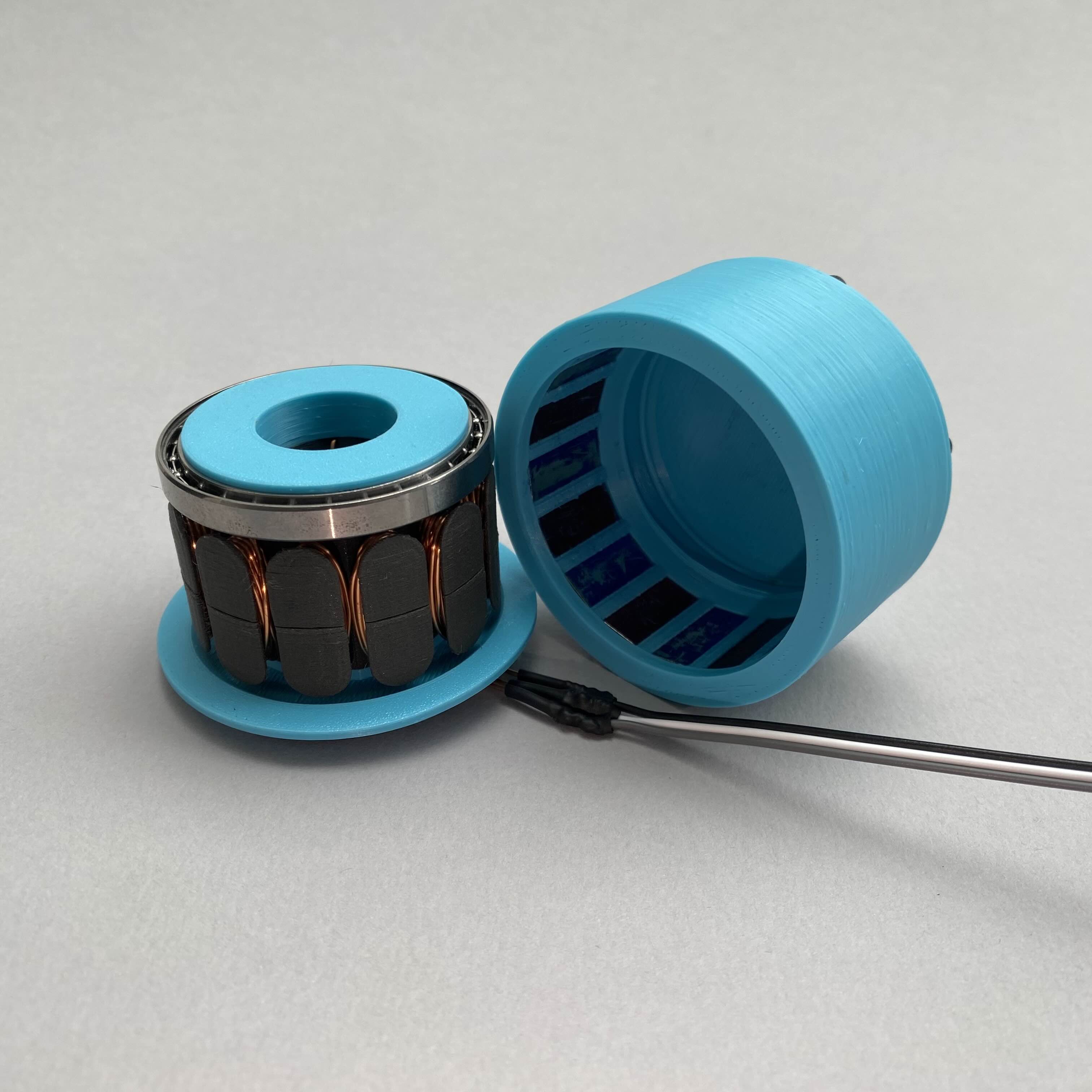

Manufacturing

The manufacturing process of the motor had to be 3d printed as it had to be made with the tools I had available. This poses some challenges as the stator of the motor should conduct as much magnetic flux as possible to increase the power of the motor. This can be done with ferromagnetic material such as iron. It is therefore possible to use an iron composite PLA for this use case, with regular PLA for the rest of the motor. The manufacturing process also took advantage of 3D printing's layered process to embed nuts and magnets into the parts as they were printed.