Project aims

The goal of this project was to gain experience with design and 3d printing by creating a CNC machine capable of producing parts for other projects and to be able to manufacture both large flat parts as well as small, more detailed parts, an example of which is shown in the form of this CNC-cut wooden topological map. To meet these requirements, a machine with a large flat cutting area and a more restricted Z height that only had to be a small multiple of the typical maximum material thickness.

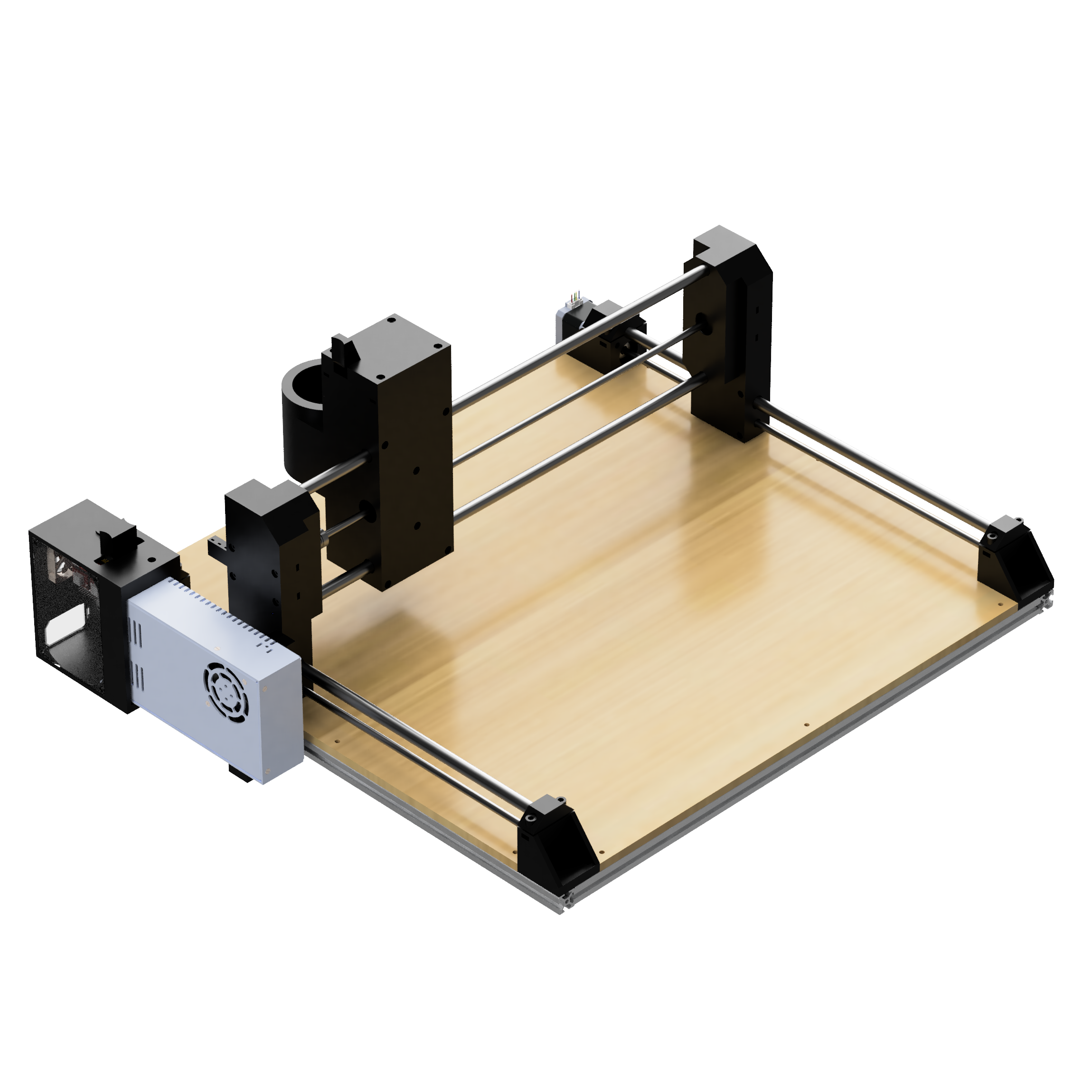

Machine design

The CNC machine was designed in Fusion 360. It used a combination of 3D models of parts from the internet and 3d models of parts to be manufactured using 3d printing and to be cut from wood. The process of designing this machine was very illuminating, and there are many things about it that could be improved that I learned through failures and limitations in the manufacture and use of this machine.

Real world applications

A good example of a recent project where the CNC machine I built has been very helpful is my spin cast ceramics project, where it has also allowed me to produce functional parts that I would not be able to produce with my 3D printer. For example, these pieces cannot be printed in one part due to size restrictions.